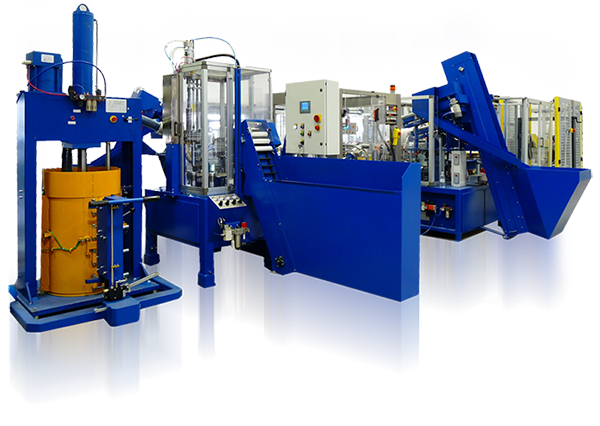

Automatic Cartridges Filling Lines

Since 1973, Nannini Renato Machinery has been designing and manufacturing complete lines for the vertical filling in cartridges, of products with any viscosity, especially medium to high/very high such as adhesives, silicone sealants (silicone), acrylic sealants, polyurethane sealants, glues, mastics, putties, pastes, lubricant greases, hard creams, dental pastes, etc.

Our complete lines for cartridges allow you to:

1. Extrude/press out the viscous product by emptying 20-25 liters pails/buckets, 200 liters drums, or directly from mixing/production tanks with an internal diameter of up to 1600 mm, thus feeding the filling machine doser.

2. Automatically dose, with care and accuracy, to fill cartridges with products of any viscosity and especially medium to high or very high.

3. Automatically cap the filled cartridges, evacuating the air between plunger and product.

4. Roll the cartridge for marking with ink-jet printing the batch number and/or expiration date.

5. Automatically pack the cartridges including their nozzles, with or without clip.

High productivity

cartridges/minute

– with the single-head filling machine,

– with 1 operator only

to palletize and refill the machines with empty cartridges, caps and cartons, as needed.

50 or 80 cartridges/minute

– with multi-head filling machines

– with two operators.

An automatic cartridge filling line is typically composed of:

1. EXTRUDER / PRESS

-

Hydraulic extruder/press model “PF200” for commercial 200 l drums/barrels, to empty the drum and feed the doser of the filling machine.

For increased productivity, we provide the system to work “in tandem” with two “PF200” extruders, making it possible you to save the drum changing time.

OR:

-

Hydraulic extruder/press for mixing/production tanks, model “PV”, or “HI”, or “EHI”, for emptying the tank and feeding the doser of the filling machine in line.

2. AUTOMATIC CARTRIDGES FILLING AND CLOSING MACHINE

A wide range of fully automatic filling machines:

- Vertical doser, to fill products of any viscosity.

- Single, double or triple head for a maximum production capacity variable, depending on the model, of 25 to over 80 cartridges per minute.

- Vertical filling of the cartridge from the bottom upwards, with controlled lowering to avoid the formation of air bubbles during filling.

- Automatic capping systems for any type of closure.

- Totally pneumatic models for ATEX potentially explosive environments, or anyway for those who prefer to use only compressed air and electro-pneumatic models for maximum performance and ease of use with automatic diagnostics, and remote-control service from our office.

- Versions also suitable for filling of aluminum cartridges, or cardboard and aluminum cartridges, with or without an integrated nozzle and from the smallest to the largest size.

- Extensive customization options: from the colors of the machines to their lay-out, to stations for nitrogen spraying, cap lubrication, weight control. Each request is carefully evaluated.

3. CARTRIDGE ROLLING MACHINE/DEVICE

Cartridge rolling machine model “GR” o “GRI” o “GRE” to roll the cartridge during the ink-jet marking of the batch number and/or expiration date.

4. AUTOMATIC PACKING MACHINE

Wide range of packing machines:

- Multisize versions for packing in cartons with 12 to 30 cartridges (optional also 6 and 8).

- Versions with or without automatic carton forming/erector device.

- Versions with the possibility of packing along with the cartridges also the nozzles with or without clip.

- Versions with different operating speed, suitable for the speed of the automatic cartridge filling machine.

5. STATIC MIXING MACHINES

All our filling lines can be completed with static mixing machines for coloring and/or catalyzing and/or extending the base product automatically in line.

Nannini Renato Custom.

Thanks to our entirely in-house Design and Production Departments, we are able to meet any customization request,

taking into full account the timing needs of your business.

Request more information.

Get in touch with us.